Technical Overview of Ce:YAG Crystal

Technical Specifications

Product Name: Cerium - doped Yttrium Aluminum Garnet Crystals

Simplified chemical formula: Ce :YAG (Cerium-doped Yttrium Aluminum Garnet)

Material: Crystalline material ( Main components: Yttrium 45%, Aluminum 22.5%, Oxygen 32.3%, Cerium 0.2% )

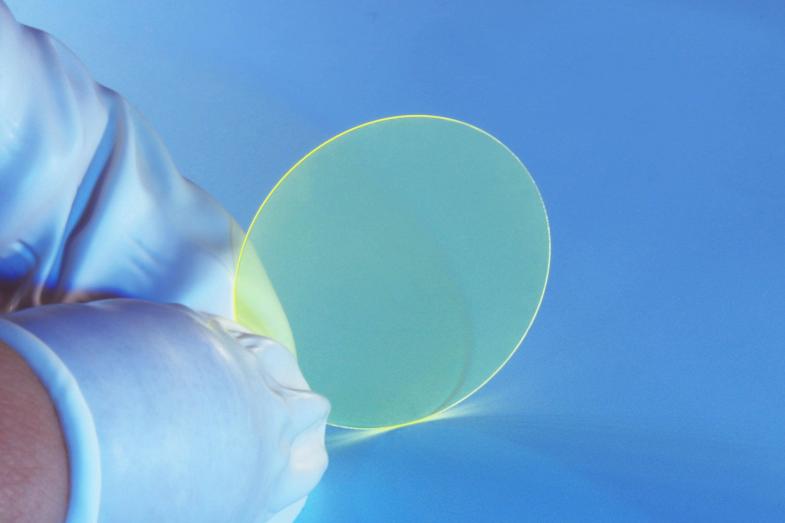

Product images:

- Product Introduction:

Cerium-doped yttrium aluminum garnet (Ce:YAG) crystal is a commonly used scintillator material that emits fluorescence under X-ray or other radiation excitation. This crystal exhibits high luminous efficiency and a wide pulse response, with an emission peak at 550 nm, which perfectly matches the sensitivity wavelength of photodiodes, making it particularly suitable for lightly charged particle detection systems using photodiodes as photodetectors. Furthermore, Ce:YAG crystal possesses advantages such as non-hygroscopicity, high-temperature resistance, and thermodynamic stability, making it suitable for applications in extreme detection environments.

In terms of manufacturing process, yttrium oxide and alumina raw materials are thoroughly mixed and then cerium oxide is incorporated. Crystals are then grown using a high-temperature chemical reaction and the Czochralski method. After growth, the crystals are cut and their end faces are polished with high precision. The external dimensions can be customized according to customer requirements .

- Working principle:

Cerium-doped yttrium aluminum garnet (Ce:YAG) emits fluorescence upon excitation by X-rays or other radiation, with a central wavelength of approximately 550 nm. The fluorescence intensity is closely related to the intensity and energy of the radiation; therefore, measuring the fluorescence signal accurately reflects the radiation intensity, enabling effective detection. When Ce:YAG is fabricated into thin sheets, it can be widely used in high-resolution soft X-ray imaging systems, improving image quality and detection accuracy.

- Production process:

- Crystal growth: Cerium-doped yttrium aluminum garnet crystals are grown in a high-temperature furnace using the Czochralski method to ensure the integrity of the material structure and the uniform distribution of chemical composition.

- Cutting: Precisely cut the crystal according to the size requirements specified by the customer.

- Precision machining: The crystal end face is parallelized, followed by fine grinding and optical-grade polishing to ensure that the surface accuracy and surface finish meet optical standards.

- Inspection and Packaging: The product dimensions, end face parallelism, and surface quality are strictly inspected. Once they meet the requirements, they are packaged in a clean environment to ensure product quality and safe use.

- Application areas:

This material can be applied in multiple fields, including fluorescence conversion of white LEDs, laser illumination, soft X-ray microscopy, and high-energy radiation detection.

Tags: Ce:YAG crystal